Beyond the Bit: How Holistic Managed Pressure Drilling (MPD) is Redefining the Well Construction Playbook in Vaca Muerta

Photo by Andrew Svk on Unsplash

Photo by Andrew Svk on Unsplash

New research shows that by expanding Managed Pressure Drilling from a point solution to a full-lifecycle philosophy, operators can safely extend lateral reach by 70%, cut tripping time in half, and take cementing off the critical path.

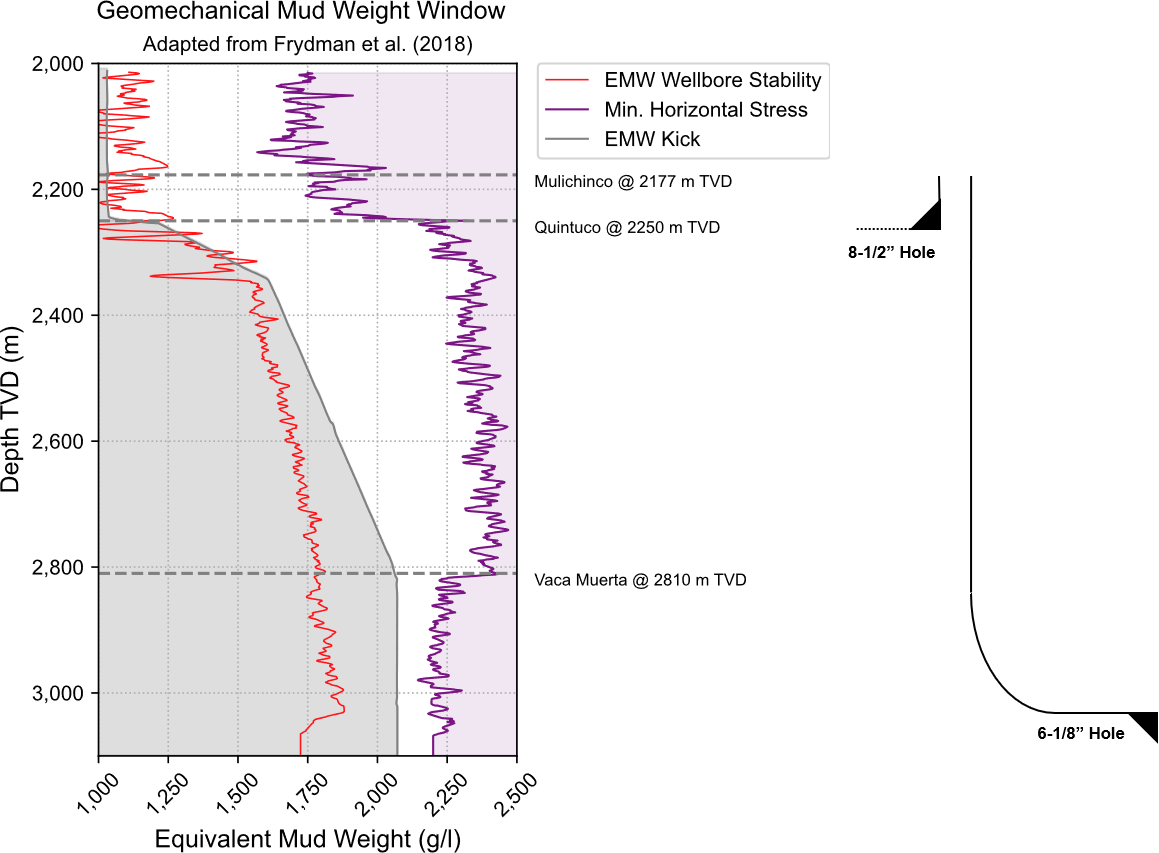

The relentless drive for longer laterals in Argentina’s Vaca Muerta field is a testament to the industry’s ambition. But with laterals now pushing past 3,200 meters (Fig. 1), operators are hitting a wall. The geomechanical complexity of the Quintuco and Vaca Muerta formations creates a narrow and unforgiving drilling window (Fig. 2), where conventional methods struggle with equivalent circulating density (ECD) management, wellbore instability, and costly non-productive time (NPT).

Fig. 1 — Year-on-Year mean reported drilled horizontal length and total frac stages per well, for Argentina unconventional Wells

Source: Secretaría de Energía (2025)

A new paper, to be presented at the IAPG 5to Congreso Latinoamericano de Perforacion, Terminacion e Intervencion de Pozos, reframes this challenge. Authored by a team from The University of Texas at Austin and SLB, the work argues for a paradigm shift: viewing Managed Pressure Drilling (MPD) not as a reactive tool for managing influx, but as a proactive, holistic system for optimizing the entire well construction process.

Fig. 2 — Production section mud weight window (left) and simplified wellbore schematic (right), after Frydman et al. (2018) (Callerio et al., 2025)

From Drilling to “Feeling” the Way Down

The foundation of this approach is a technique called Pressure Trapping MPD. By drilling with a statically underbalanced mud and allowing a small, controlled influx during connections (i.e., performing soft shut-in connections), the system provides a real-time measurement of the formation pore pressure (Fig. 3). This transforms drilling from a pre-planned execution into a dynamic, “feel-the-way-down” process.

“This real-time pore pressure mapping using soft shut-in connections effectively broadens the operational window,” explains lead author Santiago Callerio. “After a number of connections were performed, we saw an average 60 g/L reduction in the mapped pore pressure, allowing the mud weight window to expand. This was one of the keys that unlocked the ability to drill laterals up to 70% longer without inducing losses, wellbore breathing, or compromising wellbore stability.”

Fig. 3 — Connections (CNX) Surface Back-Pressure (SBP), Equivalent Static Density (ESD), and maximum Connection Gas Flow-Rate for Pressure Trapping MPD Application (Callerio et al., 2025).

The left plots show the SBP, ESD and Gas-Out values versus Depth for 4 similar wells, where each line represents one well,

whereas the right plots show the mean values plus the 95% confidence interval for these.

Two distinctive peaks can be observed in the trend lines, which correspond to the transition between Quintuco and VM (Pre-Q),

and further down the transition into VM. The mean values show an average reduction of ~60 g/L (300 psi) of the measured pore pressure.

A Paradigm Shift in Tripping and Rollovers

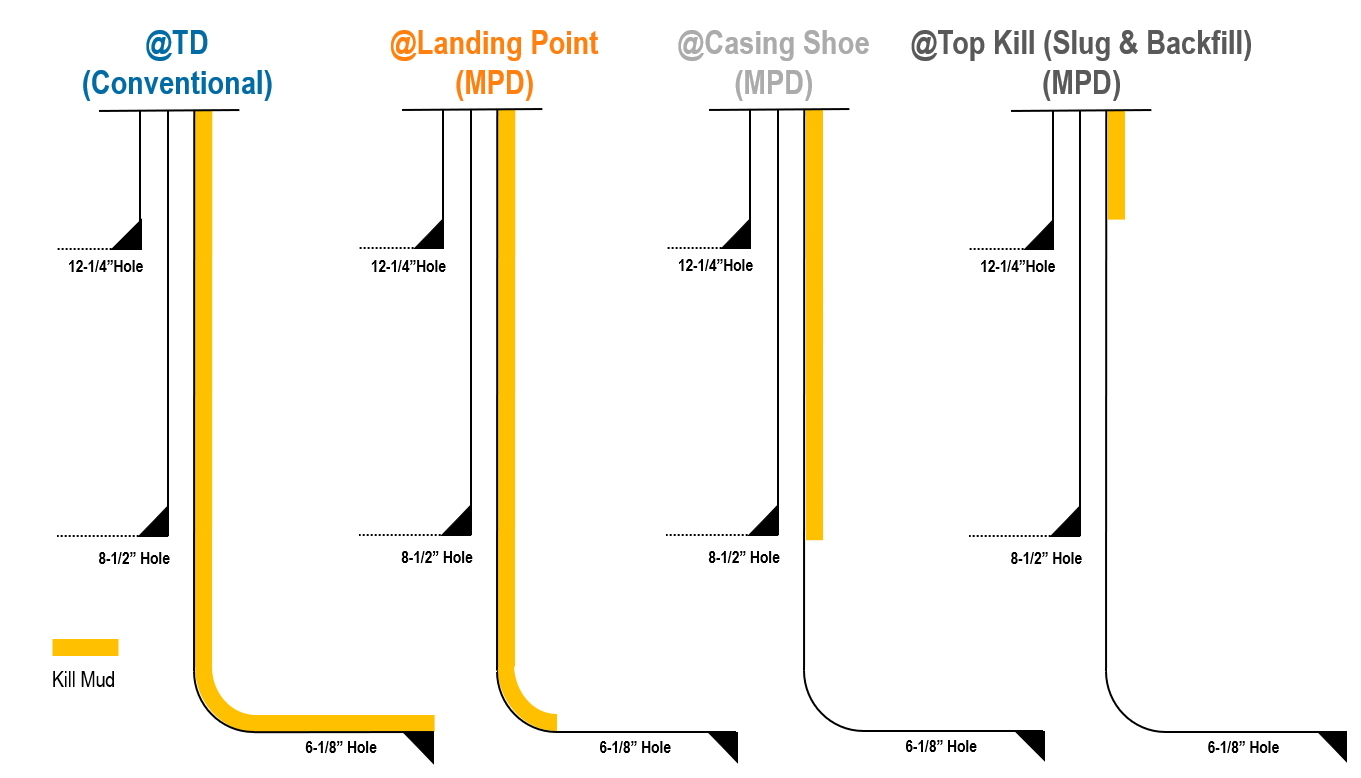

Perhaps the most significant efficiency gains were realized during tripping operations. Conventionally, tripping out of a long horizontal requires a full wellbore displacement with a heavy kill mud (KM) (Fig. 4)—a time-consuming process that risks formation damage and losses.

Fig. 4 — Schematic of wellbore and rollover kill-mud; the left-most case corresponds to the conventional case,

which requires displacing the full wellbore at TD (Callerio et al., 2025). The three ones at the right correspond to different MPD cases,

which reduce the required tripping time and net kill-mud volume

Fig. 5 — Average tripping time for each rollover depth case (Callerio et al., 2025). The conventional case requires a full wellbore displacement,

whereas the MPD cases only require displacing a small portion of the wellbore, significantly reducing tripping time.

The holistic MPD approach eliminates this. By anchoring pressure control at the maximum pore pressure depth (often much higher up the wellbore), the need for a full KM rollover is removed (Fig. 4). The team’s analysis shows this strategy:

- Reduces required kill mud volume by up to 67%, saving on fluid costs and logistics (Fig. 6).

- Cuts net tripping time by 55%, as stripping operations can be performed faster and more safely with real-time swab/surge monitoring (Fig. 5, Fig. 6).

- Reduces circulation time for the rollover by 75% (from 4.5 hours to just 1.1 hours), as only a small portion of the well needs to be displaced (Fig. 6).

Fig. 6 — Tripping and Rollover Time comparison for the different drilling methods (left), and Kill Mud Volume comparison (right) (Callerio et al., 2025). As observed, the MPD application provides an average 50% reduction on tripping and circulation time, the same for the required KM volume.

Cementing with Certainty—And Off the Critical Path

The benefits extend seamlessly into the final phases. Managed Pressure Cementing (MPC) applies the same principles of dynamic pressure control during cement placement (Fig. 7). This prevents the ECD spikes that plague conventional jobs, mitigating severe losses and ensuring complete zonal isolation. Field data cited in the paper shows an 83% success rate in avoiding remedial cementing—a major NPT driver.

As reported by Medina, Romero McIntosh and Krasuk (2015), MPC showed an 83% success rate in avoiding remedial cementing

Fig. 7 — Conventional cementing job (top), and MPC job (bottom) operating windows (Callerio et al., 2025). The MPC job shows a much wider operating window, with no ECD spikes, and a much lower risk of losses, compared to the conventional job.

The ultimate optimization, however, is offline cementing. With the well secured by the wellhead, the rig can skid to the next well and begin operations while the previous well is cemented through the MPD system and waits on cement (WOC). This parallel operation removes up to 31 hours of flat time from the rig’s critical path, delivering savings of approximately $150,000 per well.

Offline MPC reduces the critical path by 31 hours, saving around $150,000 per well (Tecpetrol, 2022)

By integrating these strategies, MPD evolves from a piece of hardware to an indispensable philosophy. It’s a field-proven playbook for building more complex wells faster, safer, and more economically—a critical enabler for unlocking the full potential of Vaca Muerta and other high-pressure unconventional plays worldwide.

For the full technical analysis, including the detailed mud weight window schematics and operational data, access the paper, “MPD AS A HOLISTIC SOLUTION FOR VACA MUERTA CHALLENGES,” presented at the IAPG 5to Congreso Latinoamericano de Perforacion, Terminacion e Intervencion de Pozos.

References

Callerio, S., Sanguinetti, C.E., Mastrangelo, L., & Toro Ibanez, J. C. (2025). MPD as a Holistic Solution for Vaca Muerta Challenges: Minimizing Well Construction Time in High-Pressure Environments. Paper presented at the IAPG 5to Congreso Latinoamericano de Perforacion, Terminacion e Intervencion de Pozos, Buenos Aires, Argentina.

Frydman, M., Acevedo, A., Miguel Castellanos, J., Casanova, O., Hasbani, J., Gutierrez, O., & Giroto, G. (2018). Reducing Drilling Risks in Highly Over-Pressurized Quintuco-Vaca Muerta Formation, a Case History in Neuquén Basin /Argentina. SPE Argentina Exploration and Production of Unconventional Resources Symposium, SPE-191839-MS. https://doi.org/10.2118/191839-MS

Medina, J., Romero Mc Intosh, C., & Krasuk, R. (2015). Cementing operation in underbalanced casing drilling: A successful case history in an unconventional shale reservoir in Argentina. Paper presented at the SPE/IADC Managed Pressure Drilling and Underbalanced Operations Conference and Exhibition 2015, SPE/IADC-173806-MS. https://doi.org/10.2118/173806-ms

Tecpetrol. (2022). Notching up another milestone on the road to optimization. https://www.tecpetrol.com/en/news/2022/notching-up-another-milestone-on-the-road-to-optimization

Secretaría de Energía. (2025). Datos de fractura de pozos de hidrocarburos (Adjunto IV) - Actualización diaria. http://datos.energia.gob.ar/dataset/datos-de-fractura-de-pozos-adjunto-iv/archivo/2280ad92-6ed3-403e-a095-50139863ab0d